Waterjet Metal and Steel

Cutting Service

Waterjet-cut, your design, fast.

Best Waterjet Metal Cutting in Bay Area

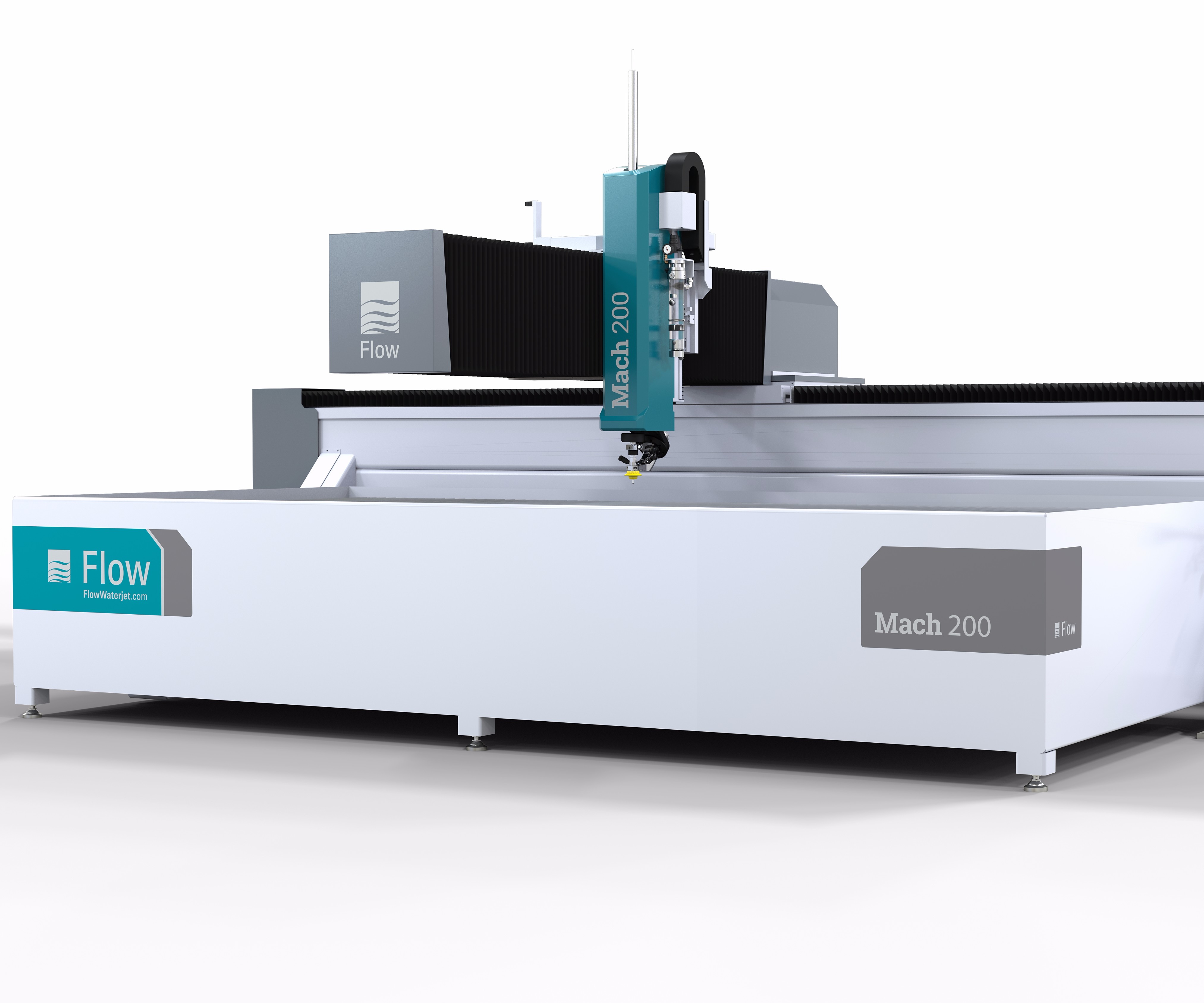

Precision waterjet cutting services from Medalco provide close tolerance, distortion-free parts with superior edge quality, no burrs, and little need for secondary finishing. We are skilled in both architectural and industrial cutting of high-quality parts from any type of metal or industrial plastic and can also handle other materials such as rubber, glass, tile and stone. A critical part of our service is to ensure customer satisfaction. You will be welcomed by a member of our professional staff when you call Medalco, not an automated answering system.

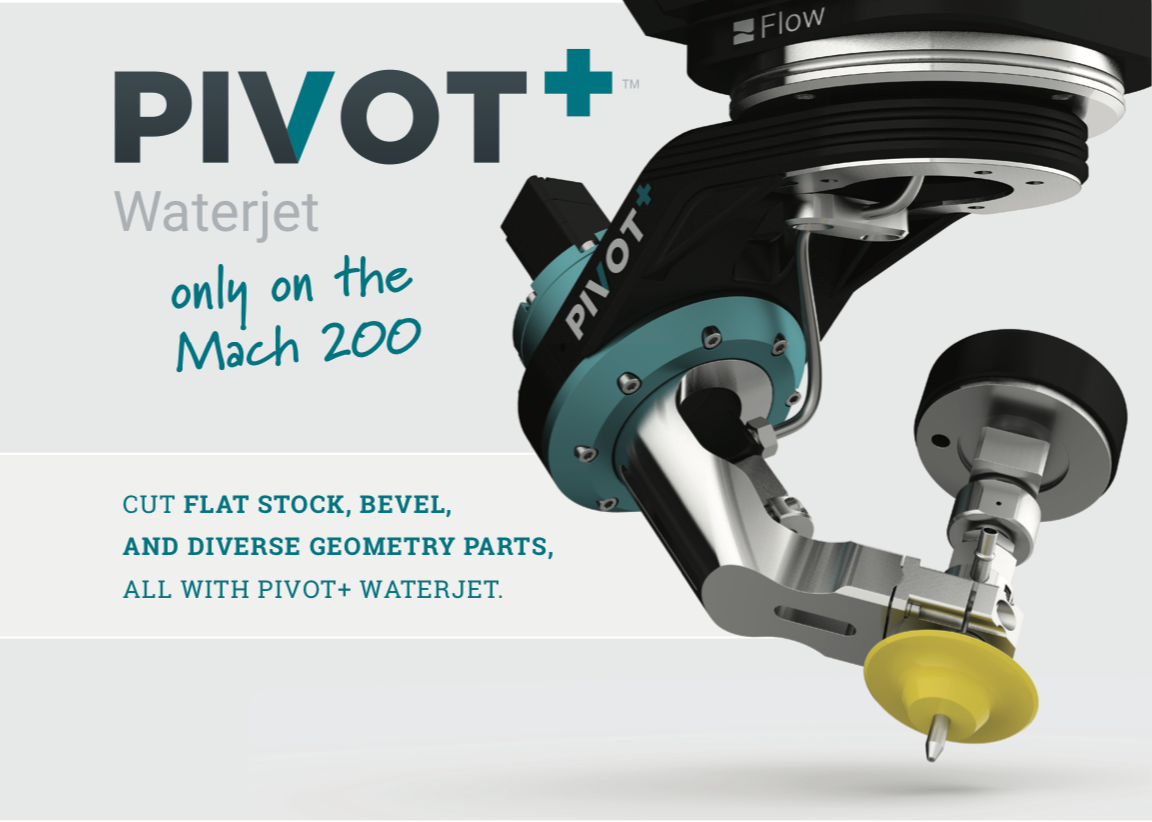

5-Axis Waterjet Cutting

Complex metal parts, especially if the design includes sharp angles and unusual shapes, can be very difficult to cut with extreme precision. Thanks to Pivot+ head, here at Medalco, we can deliver various cuts and finishes plus bevel cutting. With 5-axis head the accuracy of cuts and bevel cuts are so high. We specialize in high quality architectural and industrial cutting of any form of metal or industrial plastic, and can also handle other materials, such as concrete, steel, tile and stone.

Cutting Services

Medalco not only has extra large 13′ foot cutting table, we also have 5 Axis cutting heads and proprietary composite cutting heads you wont find anywhere else. To complete your design, we also have a fully stocked Fabrication / Machine shop. Medalco offers a cost-effective waterjet cutting solution whether you need a single part, batch of prototypes, or a production order.

Want To Be Updated With Our Newest Designs?

Just add your email and hit subscribe to stay informed.

We send our newsletter once a month, and we respect your privacy.

Error: Contact form not found.